Re: T-ASE's "Note to Practitioners"

T-ASE Home Page

T-ASE publishes foundational research with relevance to practitioners. To facilitate transfer of research into practice, each paper includes a 100-300 word "Note to Practitioners" (NtP). Within the NtP, authors step back and describe without jargon how their results could be applied to practical problems.

To Authors: writing a good NtP is a challenge. The NtP will appear just below the Abstract so it is important not to restate or repeat information that is contained in the Abstract.

The NtP should be directed to all practicing engineers in industry, colleagues who want to understand how your ideas can be put into practice. Assume such an engineer holds an undergraduate degree in a discipline other than your own, avoid jargon and notation.

Begin by specifying the practical problem(s) that motivated your work and its primary application in automation. Then describe how your solution improves efficiency, quality, productivity, or reliability. Summarize the key insights and contributions of your results and (importantly) limitations and how your work might be extended. Conclude with other possible applications of these results.

Note to Practitioners Checklist

An example NtP is below, more examples are available in each issue.

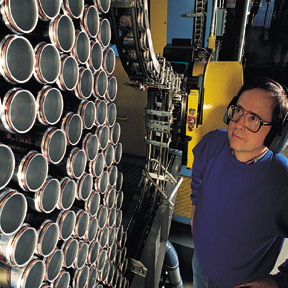

Paper Title: Unilateral Fixtures for Sheet Metal Parts with Holes

Authors: K. "Gopal" Gopalakrishnan, Ken Goldberg, Gary M. Bone,

Matthew Zaluzec, Rama Koganti, Rich Pearson, Patricia Deneszczuk

Abstract:

We propose unilateral fixtures, a new class of fixtures for sheet

metal parts with holes, where holding elements lie almost completely on

one side of the part, maximizing access for welding, assembly, or

inspection. Each primary jaw is cylindrical with a conical groove that

provides the equivalent of four point contacts and facilitates part

alignment.

We present a two-phase algorithm for computing unilateral fixtures. Phase

I is a geometric algorithm that assumes the part is rigid and applies 2D

and 3D kinematic analysis of form-closure to identify all candidate

locations for pairs of primary jaws. We prove three new grasp properties

for 2D and 3D grips at concave vertices and define a scale-invariant

quality metric based on the sensitivity of part orientation to

infinitesimal relaxation of jaw position. Phase II uses a Finite Element

Method (FEM) to compute part deformation and to arrange secondary contacts

at part edges and interior surfaces.

For a given sheet-metal part, given as a 2D surface embedded in 3D

with e edges, n concavities and m mesh nodes, Phase I takes O( e +

n^(4/3) log^(1/3) n + g log g ) time to compute a list of g pairs of primary

jaws ranked by quality. Phase II computes the location of r secondary

contacts in O( g r m^3 ) time.

Note to Practitioners:

This paper was motivated by the problem of holding sheet metal parts

for automobile bodies but it also applies to other sheet metal

components that have cut or stamped "holes." Existing approaches to

fixturing such parts generally have contacting mechanisms on both

sides of the sheet that restrict access for welding or inspection.

This paper suggests a new approach using pairs of grooved cylinders,

activated from only one side of the part (hence "unilateral"). These

cylinders mate with opposing corners of holes in the sheet and push

apart to hold the sheet in tension, thus acting as both locators and

clamps. In this paper, we mathematically characterize the mechanics

and conditions for a unilateral fixture to hold a given part. We then

show how such fixtures can be efficiently computed; this can allow a

Computer Aided Design system (with finite element capability) to

automatically generate and propose unilateral fixtures for a given

part. Preliminary physical experiments suggest that this approach is

feasible but it has not yet been incorporated into a CAD system nor

tested in production. In future research, we will address the design

of unilateral fixtures that hold two or more parts simultaneously for

welding.